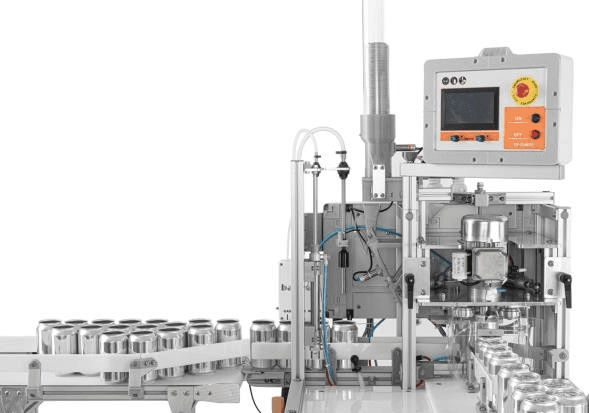

Single-line can filling machine DP-CAN/23

The canning machine DP-CAN/23 offers a quick selection of two different can filling volumes, manual height adjustment for standard classic 0.33 liter and 0.5 liter cans. Other dimensions possible by prior arrangement. Manual start-up (cooling and cleaning), capacity approx. 350 - 400 cans 0.33 liters/hour (depending on the cooled liquid and pressure)..

Features

The device is manufactured in accordance with CE standards and has a built-in 5 inch color LCD display controlled by a microprocessor, which graphically displays the operation in different languages (Slo, Ang), reports possible errors, prevents operation without proper conditions and warns of handling irregularities, while offering the possibility of various manual settings and functions. It displays the current and total quantity of cans produced and the operating time.

The housing is made of a combination of aluminum and and POM food-safe contact material. It includes an automatic conveyor feeding belt for cans, automatic feeding and closing of standard can plugs (caps).

(For carbonated drinks) minimum of 1.0 bar of constant pressure in the beer tank (from 1 to max 3 ° C), constant CO2 gas supply must be provided for the proper filling. 6.0 bar of constant air pressure is needed for the operation of the pneumatic cylinders.

Standout benefits

Easy handling;

Touch control panel;

Quick change of filling volume;

De oxidation of cans,

Automatic filling and capping;

Fast setting of different can sizes;

Sound and written notifications on the color LCD with a graphic display;

Easy LCD-guided cleaning…

Technical characteristic

Filling device dimensions:

Height: 1800 mm,

Depth: 760 mm,

Width: 650 mm

Weight: 46 Kg

Power supply:

Voltage: 110-240 V

El. power: 30 W,

El. current: 1,3 A,

Frequency: 50 Hz

El. protection: 10 A, (220-240 V)

Water protection: IP 55

Included in the package

up to 3 m insulated inlet pipe 3/8" with ½" tank connection (on the tank, the connection is provided by the customer)

up to 3 m 3/8" Co2 gas supply hose

up to 3 m pneumatic hose Ø 6 mm for air inlet

air control group with condensate drain filter and air pressure relief valve

automatic height-adjustable feed of empty cans on a conveyor belt

height-adjustable, full-can stacking table

video operation - device test

video instructions on a USB stick

written instructions

spare parts

Price: 17.577,00 EXW factory, Slovenia

Standard production time: 6 to 8 weeks after downpayment (must be oficially confirmed before order)

The canning machine DP-CAN/23 offers a quick selection of two different can filling volumes, manual height adjustment for standard classic 0.33 liter and 0.5 liter cans. Other dimensions possible by prior arrangement. Manual start-up (cooling and cleaning), capacity approx. 350 - 400 cans 0.33 liters/hour (depending on the cooled liquid and pressure)..

Features

The device is manufactured in accordance with CE standards and has a built-in 5 inch color LCD display controlled by a microprocessor, which graphically displays the operation in different languages (Slo, Ang), reports possible errors, prevents operation without proper conditions and warns of handling irregularities, while offering the possibility of various manual settings and functions. It displays the current and total quantity of cans produced and the operating time.

The housing is made of a combination of aluminum and and POM food-safe contact material. It includes an automatic conveyor feeding belt for cans, automatic feeding and closing of standard can plugs (caps).

(For carbonated drinks) minimum of 1.0 bar of constant pressure in the beer tank (from 1 to max 3 ° C), constant CO2 gas supply must be provided for the proper filling. 6.0 bar of constant air pressure is needed for the operation of the pneumatic cylinders.

Standout benefits

Easy handling;

Touch control panel;

Quick change of filling volume;

De oxidation of cans,

Automatic filling and capping;

Fast setting of different can sizes;

Sound and written notifications on the color LCD with a graphic display;

Easy LCD-guided cleaning…

Technical characteristic

Filling device dimensions:

Height: 1800 mm,

Depth: 760 mm,

Width: 650 mm

Weight: 46 Kg

Power supply:

Voltage: 110-240 V

El. power: 30 W,

El. current: 1,3 A,

Frequency: 50 Hz

El. protection: 10 A, (220-240 V)

Water protection: IP 55

Included in the package

up to 3 m insulated inlet pipe 3/8" with ½" tank connection (on the tank, the connection is provided by the customer)

up to 3 m 3/8" Co2 gas supply hose

up to 3 m pneumatic hose Ø 6 mm for air inlet

air control group with condensate drain filter and air pressure relief valve

automatic height-adjustable feed of empty cans on a conveyor belt

height-adjustable, full-can stacking table

video operation - device test

video instructions on a USB stick

written instructions

spare parts

Price: 17.577,00 EXW factory, Slovenia

Standard production time: 6 to 8 weeks after downpayment (must be oficially confirmed before order)

The canning machine DP-CAN/23 offers a quick selection of two different can filling volumes, manual height adjustment for standard classic 0.33 liter and 0.5 liter cans. Other dimensions possible by prior arrangement. Manual start-up (cooling and cleaning), capacity approx. 350 - 400 cans 0.33 liters/hour (depending on the cooled liquid and pressure)..

Features

The device is manufactured in accordance with CE standards and has a built-in 5 inch color LCD display controlled by a microprocessor, which graphically displays the operation in different languages (Slo, Ang), reports possible errors, prevents operation without proper conditions and warns of handling irregularities, while offering the possibility of various manual settings and functions. It displays the current and total quantity of cans produced and the operating time.

The housing is made of a combination of aluminum and and POM food-safe contact material. It includes an automatic conveyor feeding belt for cans, automatic feeding and closing of standard can plugs (caps).

(For carbonated drinks) minimum of 1.0 bar of constant pressure in the beer tank (from 1 to max 3 ° C), constant CO2 gas supply must be provided for the proper filling. 6.0 bar of constant air pressure is needed for the operation of the pneumatic cylinders.

Standout benefits

Easy handling;

Touch control panel;

Quick change of filling volume;

De oxidation of cans,

Automatic filling and capping;

Fast setting of different can sizes;

Sound and written notifications on the color LCD with a graphic display;

Easy LCD-guided cleaning…

Technical characteristic

Filling device dimensions:

Height: 1800 mm,

Depth: 760 mm,

Width: 650 mm

Weight: 46 Kg

Power supply:

Voltage: 110-240 V

El. power: 30 W,

El. current: 1,3 A,

Frequency: 50 Hz

El. protection: 10 A, (220-240 V)

Water protection: IP 55

Included in the package

up to 3 m insulated inlet pipe 3/8" with ½" tank connection (on the tank, the connection is provided by the customer)

up to 3 m 3/8" Co2 gas supply hose

up to 3 m pneumatic hose Ø 6 mm for air inlet

air control group with condensate drain filter and air pressure relief valve

automatic height-adjustable feed of empty cans on a conveyor belt

height-adjustable, full-can stacking table

video operation - device test

video instructions on a USB stick

written instructions

spare parts

Price: 17.577,00 EXW factory, Slovenia

Standard production time: 6 to 8 weeks after downpayment (must be oficially confirmed before order)